When a screening plant already equipped with polyurethane media suffers from clogging or gouging problems, there are synthetic solutions that can solve these problems.

The simplest solution is to switch from square mesh to rectangular mesh. As the mesh opening is larger, this would facilitate the passage of products that tend to clog or plug square meshes. While rectangular meshes have the advantage of improving throughput, they also have a number of shortcomings that could adversely affect production quality.

Another solution to reduce dowelling would be to reduce the hardness of the screening surface. As the polyurethane layer is softer and more supple, it will tend to deform more easily as the material passes through, thus allowing the product to pass more easily through the mesh.

GIRON therefore offers two polyurethane solutions that can reduce or solve clogging or gouging problems during dry or underwater screening.

The Polytech web

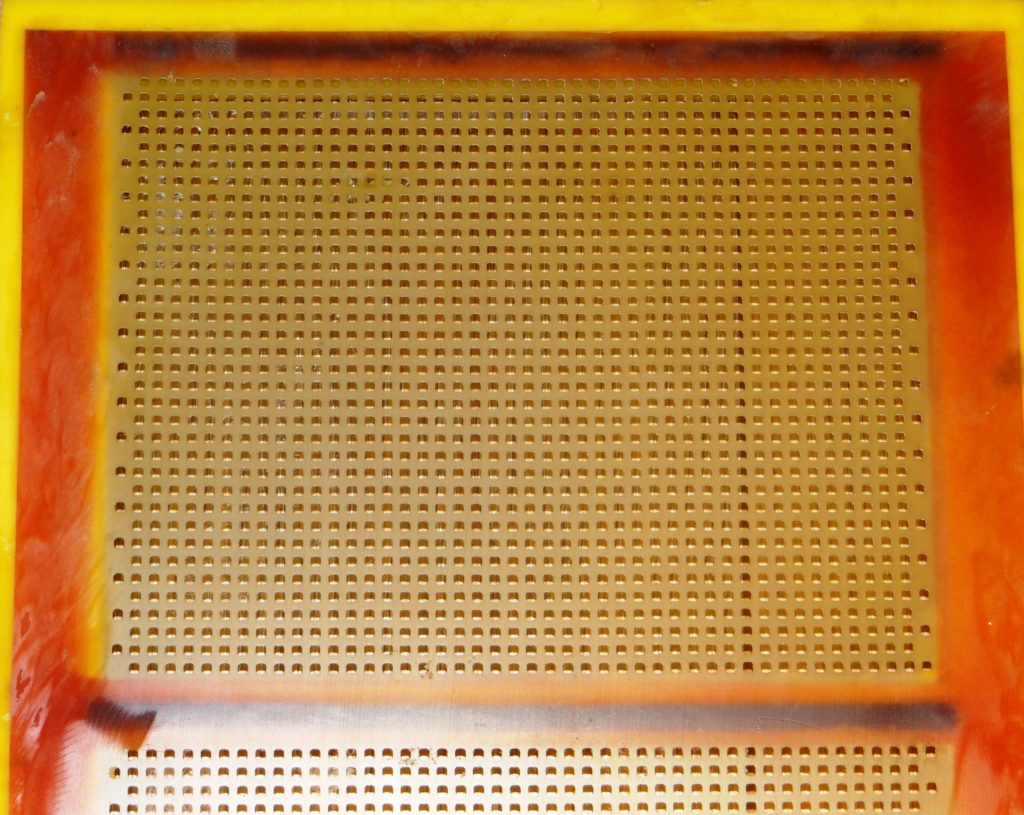

Polytech fabric is an evolution of polyurethane stretched fabrics. In order to solve the problems of clogging and/or doweling, standard features such as the bar, the diameter of the stainless steel wire rope and the thickness of the material to be worn have been restricted to a minimum.

As a result, the percentage of void (permeability) of the screening surface has been increased and the wear thickness optimized to facilitate the passage of materials. The result is a high-permeability polyurethane fabric with anti-clogging and anti-jamming properties. This fabric is relatively lightweight and flexibleIt can be rolled up and easily transported.

To be tensioned, these cloths are made with tensioning hooks, also known as "tensioning hands". These are steel sheets bent at an angle to suit the various screens.

To operate a screen, it must be correctly tensioned. It must also follow a certain curve defined by screen manufacturers. The thicker the fabric, the greater the curvature required for good support. To ensure that the canvas sits more securely on the frame, solid zones are provided on the canvas at the level of each transverse support.

The use of this type of fabric requires particular attention during installation, and especially when it comes to tensioning. Our teams are at your side to help you install Polytech fabrics correctly.

It is also important to take into account the granulometry that Polytech will receive.

GIRON offers a wide range of mesh sizes (W) to meet the needs of its customers.

Standard range :

- Square mesh: 2 mm ≤ W ≤ 35 mm

- Maximum dimensions: 2.5 m EXT x 1.5 m

- Options: Covering flaps, reinforcing brackets, holes for central mounting, etc.

The Polyflex module

Polyflex is a polyurethane module in which the screening zone has been replaced by a prestressed membrane bonded and thin-walled. Also known as drumhead "This solution has been around for a very long time.

The polyurethane formulation used here is different from traditional polyurethane meshes and modules. This solution is mainly used in modular panels for screening clogging products thanks to its trampoline effect and where permeability is more important than abrasion resistance.

Polyflex can also be supplied as a woven fabric. In this case, GIRON recommends Polytech fabric, which will meet your expectations with much better value for money.

It is important to take into account the granulometry that Polyflex will receive, as it will not be able to accept heavy loads.

GIRON offers a wide range of mesh sizes (W) to meet the needs of its customers.

Standard range :

- Mesh size: 1.6 mm ≤ W ≤ 60 mm

- Thicknesses: 2 mm ≤ e ≤ 7 mm