CUSTOMER CASES

GIRON has always positioned itself as ≪ technical solutions provider ≫ demanding customers, sensitive to cost per ton screened. Compliance with the particle size distribution curve, which determines the value of screened products, depends on the quality of the cloth used.

In response to screening problems, the GIRON company has been continuously developing for a century unique know-how for the design and manufacture of screening cloths. Specific production resources and all tooling are designed and produced in-house, enabling us to control all our manufacturing processes and offer the highest quality products. high-performance products.

GIRON's commitment to efficiency and performance has led the company to adopt a transparent, quality-oriented approach that respects society and the environment.

-

Clogging or pegging problems

Overview Clogging: clogging of the meshes due to moisture in the product fines in the case of screening known as [...].

-

How to mount your anti-clogging fabric

Overview Certain precautions need to be taken when handling anti-clogging cloths, to avoid the risk of damage [...].

-

Improve the lifespan of your fabrics

Presentation On a basis of being equipped with a steel screen: On a basis of being equipped with a steel screen: On a basis of being equipped with a steel screen: On a [...]

-

Troubleshooting

Presentation In order to be able to respond to emergency situations as quickly as possible, GIRON has [...].

-

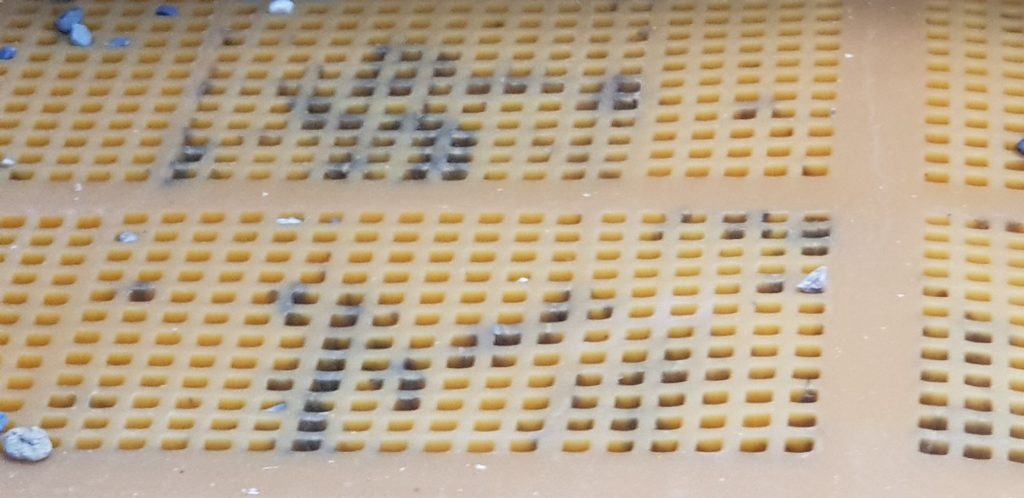

My polyurethane fabric is disintegrating (stains)

Presentation For many years now, we've been seeing the random appearance of this problem of attacks on polyurethane products. [...]

-

Choosing your hook

Presentation Crochet hooks on wires Crochet hooks directly on wires may seem at first sight less expensive for [...].

-

How does canvas wear?

Presentation Fabrics tend to flatten under the effect of product abrasion. Abrasion is a phenomenon that occurs through displacement and/or [...].

-

Increase my flow

Presentation On a base to be equipped with a classic steel screen: On a base to be equipped with a classic steel screen: On a base to be equipped with a classic steel screen: On a base to be equipped with a classic steel screen: On a base to be equipped with a classic steel screen: On a [...]