As polyurethane meshes have a high elongation capacity, they need to be reinforced with steel cables to ensure that the mesh opening is maintained, and also to guarantee good mechanical resistance to tension, whether mounted in lateral tension (perpendicular to the product feed) or in longitudinal tension (parallel to the product feed).

To be tensioned, these cloths are made with tensioning hooks, also known as "tensioning hands". These are steel sheets bent at an angle to suit the various screens. The hooks are connected to the synthetic screening surface by a bolting system attached to steel cables or wires that are molded into the material.

To operate a screen, it must be correctly tensioned. It must also follow a certain curve defined by screen manufacturers. The thicker the fabric, the greater the curvature required for good support. To ensure that the canvas sits more securely on the frame, solid zones are provided on the canvas at the level of each transverse support.

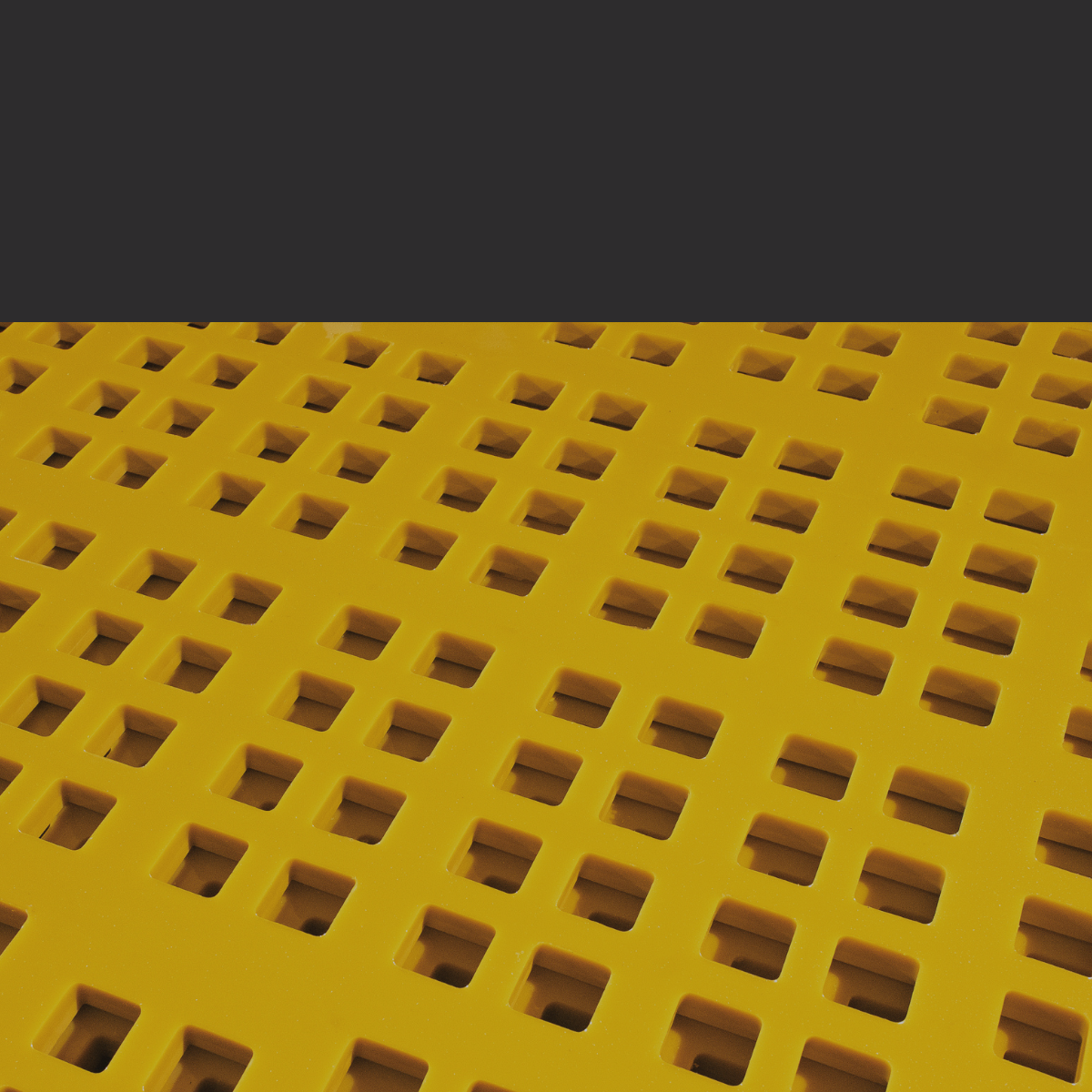

GIRON offers a wide range of mesh sizes (W) to meet the needs of its customers.

Standard range: (for other dimensions, please consult us)

- Square mesh: 3 mm ≤ W ≤ 150 mm

- Rectangular mesh: 4 x 10 mm ≤ W ≤ 27.5 x 61 mm

- Injection cracks: 0.2 x 11 mm ≤ W ≤ 1.5 x 11 mm

- Mesh size: in rows or in staggered rows

Synthetic fabrics can be manufactured in self-supporting versions, or on welded frames that can be bolted or clamped to a frame.