This unique concept, invented and patented by GIRON in 1997 is an innovative and exclusive solution to certain screening problems:

- Increase longevity of your steel fabrics, maintaining your permeability

- Improving performance for your polyurethane fabrics

- Optimizing evacuation washing water on a polyurethane-equipped screen

Guaranteed benefits

- up to x 2 the permeability of your polyurethane systems

- up to 8 times longer service life for your classic steel installations

These fabrics can be fitted with hooks (lateral or longitudinal tension), mounted on frames or manufactured in modules. They are a high-performance replacement for your traditional equipment, with no real anti-clogging vocation.

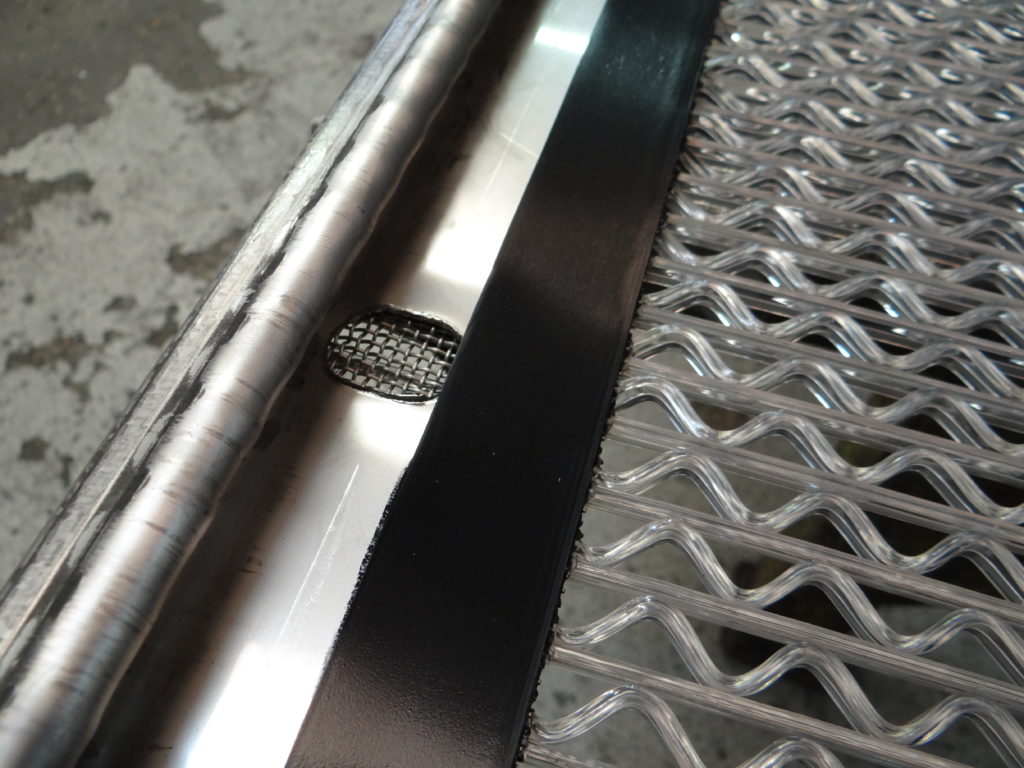

To be tensioned, these cloths are made with tensioning hooks, also known as "tensioning hands". These are steel sheets bent at an angle to suit the various screens. The hooks are connected to the synthetic screening surface by incorporating the straight profiles into the bending of the sheets.

To operate a screen, it must be correctly tensioned. It must also follow a certain curve defined by screen manufacturers. The thicker the fabric, the greater the curvature required for good support. To ensure that the canvas sits more securely on the frame, solid zones are provided on the canvas at the level of each transverse support.

Standard range :

- Rectangular mesh: 4 mm ≤ W ≤ 35 mm

- Profiles: 3×6 / 3.5×8 / 4×11 / 6×13 / 8.5×18.5

- Options: Covering flaps, reinforcing brackets, holes for central mounting, etc.

The origins of Polymixte

In the field of screening surfaces, the fighting wear and tear has always been a major concern. A number of solutions to wear problems have been found, including the switch from steel to polyurethane, which is undoubtedly the most significant event of recent years.

A screening surface, whether metallic or synthetic, is essentially defined by its mesh, a hole framed by material whose primary purpose is to ensure the passage of a maximum amount of material with a desired particle size cut-off.

The choice of material has an impact on the expected results, depending on whether wear resistance or abrasion resistance is favored, i.e. the service life sieves, or conversely if you choose the permeabilityproduction volume per tonne produced per hour.

If you choose a very rigid material, such as high-strength steel, you can be satisfied with putting a small amount of material between each hole, to ensure that the mesh holds its shape. If, on the other hand, you opt for a softer material such as rubber or polyurethane, you'll need to add more material to guarantee the mesh's dimensional stability.

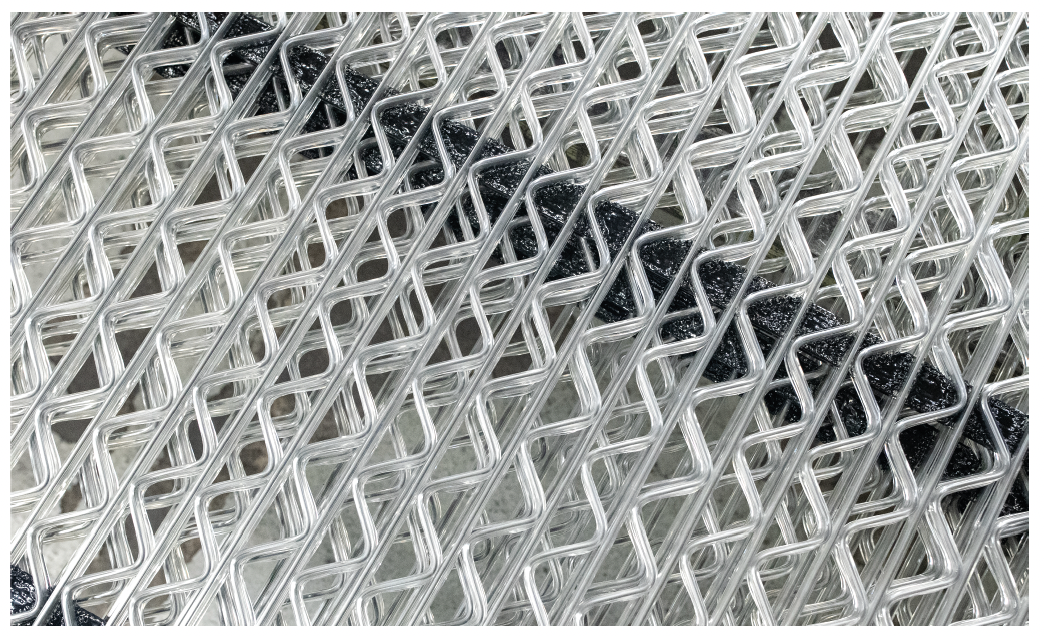

Steel wire coated with a wear-resistant synthetic material has been known for many years as a potentially interesting solution. The GIRON company has been involved in this field since the early 80s. While the round cross-section of the composite wire was initially the logical extension of a traditional steel wire, the identification of the active parameters and their systematic and exclusive optimization in terms of abrasion resistance, permeability and mechanical strength, has enabled us to create a hybrid screening surface.

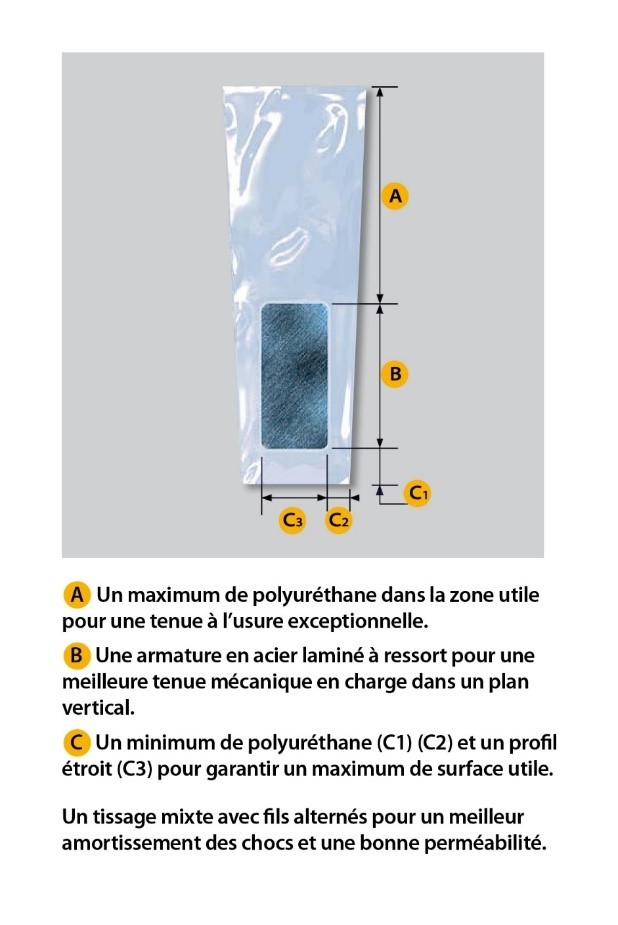

The principles of Polymixte are therefore established:

- polyurethane (A) in the upper part and in sufficient thickness to guarantee good impact resistance and abrasion resistance

- a rectangular steel frame (B) at the bottom to optimize vertical rigidity and mechanically support the product load

- a lower layer (C1) which is restricted because it is not subject to abrasion

- a reduced side layer (C2) to maximize permeability

- finally, a hybrid composite profile with a trapezoidal cross-section to facilitate material flow and limit dowelling.