Invented and patented by GIRON in the 1950s, anti-clogging fabrics are now widely available throughout the world. It's a flagship product for our company, which knows all its secrets.

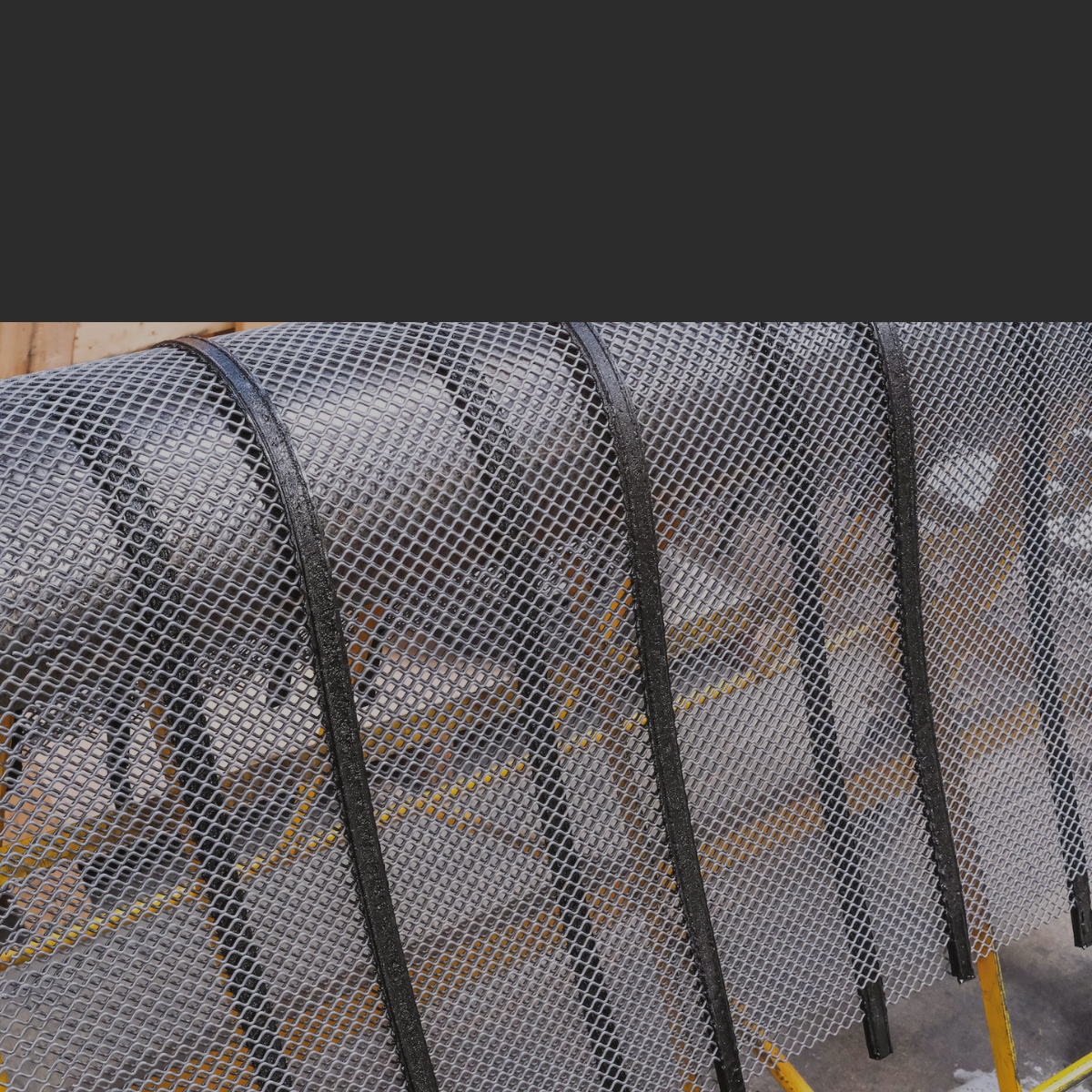

These vibrating-wire meshes are made up of preformed, independent high-strength steel chains, juxtaposed in the horizontal plane. These wires are held together by vulcanized rubber or polyurethane wefts, ensuring that the cut is maintained until the wire is completely worn.

The result is a one-piece, perfectly flat screening surface with high flexibility and a thickness limited to a single steel wire. Not surprisingly, this type of weave is widely used to improve abrasion resistance, especially as its properties are so well known. anti-clogging and anti-clogging performanceand therefore screening efficiencyThis allows us to choose thread diameters greater than those used in the manufacture of conventional fabrics.

They are available in square, triangular, rectangular or sinusoidal mesh, in high-strength steel or stainless steel.

"In a screening plant, the right choice of screen cloth is crucial, as it determines the product's particle size curve and the screen's output. The screen fabric manufacturer is faced with 2 constraints:

Robert Giron

- the screen itself with its mechanical characteristics (frame, vibrations) ;

- the product, which is almost of a living nature since it is natural (shape, hardness, humidity, etc.).

Experience has shown that the use of an anti-clogging screen cloth can considerably improve screening performance, or better still, make possible screening for which no solution had been found.

This led us to devise several types of anti-clogging fabric, one of which would provide the optimum result.

Inventor of anti-clogging fabrics

Square mesh

ONDAP

ONDAP square mesh is designed for use on vibrating screens with longitudinal or lateral tensioning systems.

Use

These canvases serve several purposes:

1. Keep a screening surface virtually intact despite the presence of fine clayey or moist elements, which tend to clog an ordinary screen cloth.

2. Limit or even eliminate doweling on crushed products.

3. Improve throughput of a sieve that is too dimensionally accurate due to their high permeability.

4. In the case of high abrasion by fine products under water, with an unrivalled service life, by reinforced series.

Features

Channels The warp threads are independent of each other and form square meshes, with one diagonal running in the direction of product feed.

As the chains are independent of each other, the shocks produced by the elements to be screened cause differences in vibration that prevent the fine elements from clumping together from one wire to another (clogging).

Then, with a thickness of 50% less than the screening cloths classicsas the wires do not cross each other, which explains their high permeability and their high wear resistanceas a result of reduced friction.

Frames The use of abrasion-resistant rubber or polyurethane instead of steel wire or pre-cut sheet metal wefts was a major improvement at the time.

The wefts, which are necessarily raised in relation to the actual screening surface and therefore subjected to the harshest of screening stresses, are virtually indestructible thanks to the unquestionably superior abrasion resistance of rubber or polyurethane.

The wefts form a one-piece unit, so there's no possibility of lapping by screening fines, which ensures a much longer service life.

This design also makes it possible to obtain a softer canvas so more efficient at vibrationThe wires are no longer constrained by the steel frames.

Special features

Depending on its use, the particular characteristics of your products or your operating conditions, the screening result obtained with an ONDAP fabric may vary.

GIRON will bring you all the tips necessary to find the optimal solution in terms of :

- the wire diameter to be selected (light to heavy-duty series)

- the spacing between raster bands

- steel, rubber or polyurethane weft strips

Standard range

Mesh 0.8 mm to 100 mm.

Wires 0.6 mm to 7 mm.

Triangular mesh

MIXED

MIXED fabric with triangular mesh, featuring alternating ONDAP and straight wires, is designed for use on vibrating screens with longitudinal or lateral tensioning systems.

Use

These canvases can be used in a variety of situations:

1. In the case of a fine cut on a high grain size.

2. In the event of shocks or high loads are to be feared.

Features

Channels

The warp threads, alternating wavy and straight, are independent of each other and form triangular meshes.

As the chains are independent of each other, the shocks produced by the elements to be screened cause differences in vibration that prevent the fine elements from clumping together from one wire to another (clogging).

In addition to this phenomenon, which is identical to ONDAP, the possibility of alternating wavy and straight wires of different diameters also causes a variation in vibration amplitude, accentuated by the fact that one wire is taut and the other free.

Secondly, with a thickness 50% less than conventional screening cloths, the wires do not cross, which explains their high permeability and their high wear resistanceas a result of reduced friction.

Frames

The use of abrasion-resistant rubber or polyurethane instead of steel wire or pre-cut sheet metal wefts was a major improvement at the time.

The wefts, which are necessarily raised in relation to the actual screening surface and therefore subjected to the harshest of screening stresses, are virtually indestructible thanks to the unquestionably superior abrasion resistance of rubber or polyurethane.

The wefts form a one-piece unit, so there's no possibility of lapping by screening fines, which ensures a much longer service life.

This design also makes it possible to obtain a softer canvas so more vibration-efficientThe wires are no longer constrained by the steel frames.

Special features

Depending on its use, the particular characteristics of your products or your operating conditions, the screening result obtained with a MIXED screen cloth may vary.

GIRON will give you all the advice you need to find the best solution for your choices:

- the wire diameter(s) to be selected (Ondap and straight wire)

- the spacing between raster bands

- steel, rubber or polyurethane weft strips

Standard range

Mesh 1.6 mm to 55 mm.

Wires 1 mm to 8 mm.

Open mesh

ZIG-ZAG

ZIG-ZAG fabric is the fabric that provides the best possible improved anti-clogging performanceThis is due to the absence of any contact between the screening wires.

The amplitude, curvature and wavelength parameters characterizing the shape of the warp yarn generate a very wide adaptation potential.

In this way, the passage of flat or long elements can be minimized by acting on one or more of these parameters to determine a virtually closed mesh.

Use

These canvases are mainly for severe clogging.

Features

Channels

The warp threads are independent of each other and form open meshes.

As the chains are independent of each other, the shocks produced by the elements to be screened cause differences in vibration that prevent the fine elements from clumping together from one wire to another (clogging).

In addition to this phenomenon, which is identical to ONDAP, the possibility of adjusting the corrugation height provides a wide range of solutions.

Secondly, with a thickness 50% less than conventional screening cloths, the wires do not cross, which explains their high permeability and their high wear resistanceas a result of reduced friction.

Frames

The use of abrasion-resistant rubber or polyurethane instead of steel wire or pre-cut sheet metal wefts was a major improvement at the time.

The wefts, which are necessarily raised in relation to the actual screening surface and therefore subjected to the harshest of screening stresses, are virtually indestructible thanks to the unquestionably superior abrasion resistance of rubber or polyurethane.

The wefts form a one-piece unit, so there's no possibility of lapping by screening fines, which ensures a much longer service life.

This design also makes it possible to obtain a softer canvas so more efficient at vibrationThe wires are no longer constrained by the steel frames.

Special features

It should be noted that each ZIG-ZAG fabric, more than any other ONDAP or MIXED anti-clogging fabric, requires an even more precise approach to the conditions of use, in order to define the characteristics that best solve the problem posed by the screened materials.

GIRON will give you all the advice you need to find the best solution for your choices:

- the wire diameter to be selected

- wave shape

- the spacing between raster bands

- steel, rubber or polyurethane weft strips

Standard range

Mesh 0.7 mm to 60 mm.

Wires 0.6 mm to 7 mm.

LONPLAN

These rectangular mesh with long, parallel wires are absolutely flat.

They are primarily used for dewatering sands and as wear cloths for water loss in the case of screening under heavy washing, when the screen, generally with lateral tension, comprises several successive cloths.

In this case, the first mesh may be half the size of the square mesh.

Features

Channels

The chains are uniformly straight. No crimping or stamping operations are used to harden the wire or modify the structure of the steel. This makes it possible to use very high-strength steel wires or spring-loaded stainless steel wires.

This gives LONPLAN fabric unrivalled mechanical and abrasion resistance.

Frames

The wefts are made up of metal frames embedded in abrasion-resistant rubber, which together with the warps are vulcanized under pressure to form a one-piece unit, making it impossible for the wires to move or run in one another.

Rubber belts can be replaced by polyurethane belts, which can meet certain food standards, for example.

Special features

Depending on its use, the particular characteristics of your products or your operating conditions, the screening result obtained with a LONPLAN screen cloth may vary.

GIRON will give you all the advice you need to find the best solution for your choices:

- the wire diameter to be selected

- the spacing between raster bands

- steel, rubber or polyurethane weft band.

Standard range

Mesh 0.5 mm to 60 mm.

Wires 1.6 mm to 8 mm.

PIANO ROPE

These rectangular mesh with long, parallel wires are absolutely flat.

Piano strings are more often mounted on mobile screens in longitudinal tension. It is highly anti-clogging and permeable. However, its cut may lack precision in certain applications. Its combs movable allow it to adapt easily to the screen supports.

Standard range

Mesh 1 mm to 30 mm.

Wires 0.8 mm to 3 mm.