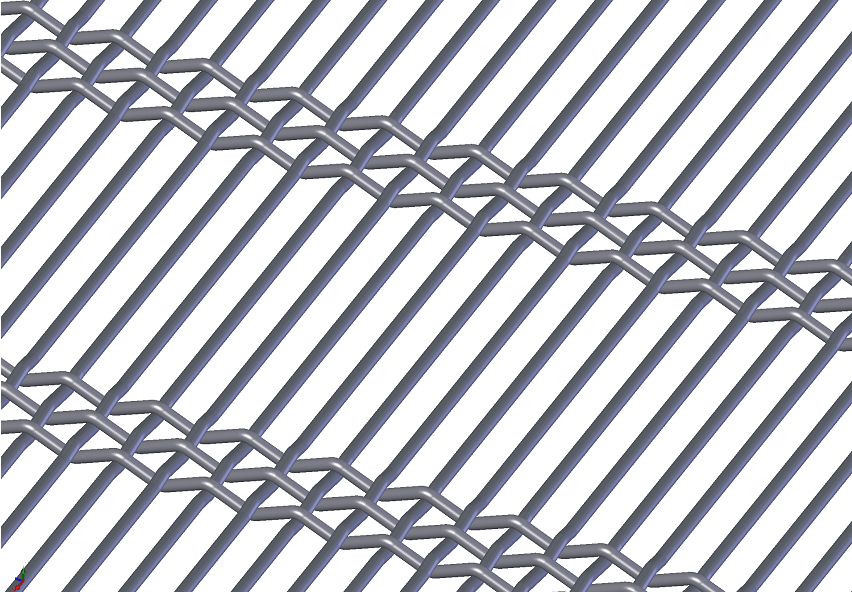

These cloths are designed to meet the screening needs of abrasive materials, as encountered in the extractive industries.

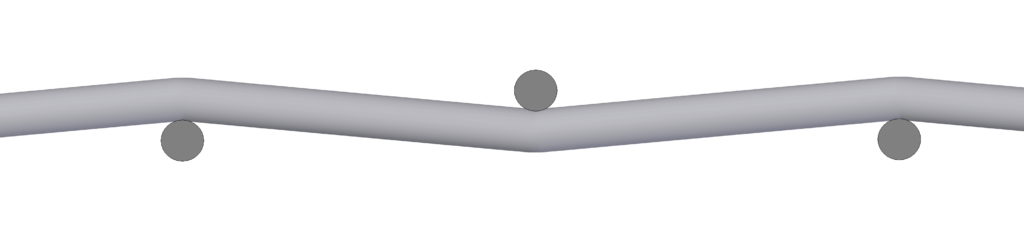

Warp and weft threads are here preformed before weaving. They are therefore corrugated or notched, enabling steel wires up to 20 mm in diameter to be woven.

The steel used is mainly high resistancewith a carbon content of at least 0.5% and a tensile strength of between 900 N/mm² and 2000 N/mm², naturally dependent on the wire cross-section used. Stainless steels are essentially nickel-chromium base alloys. They may include variable molybdenum contents, depending on the environment in which they are used.

In order to be able to respond to emergency situations in the shortest possible time, GIRON has set up a permanent inventory 12,000 square meters of steel mesh, representing around 200 mesh/wire references, in the most common square meshes.

This stock enables us to guarantee same-day dispatch for orders received before 11am.

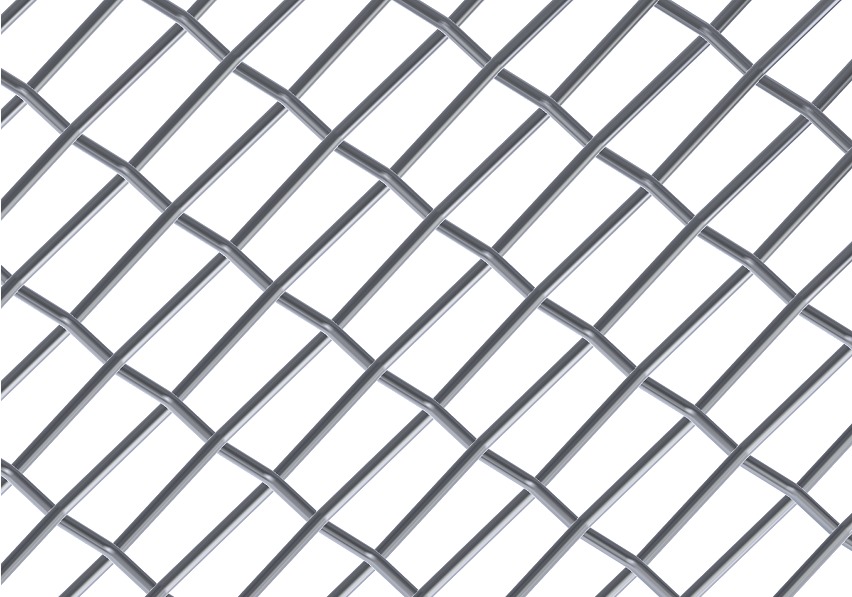

Square mesh

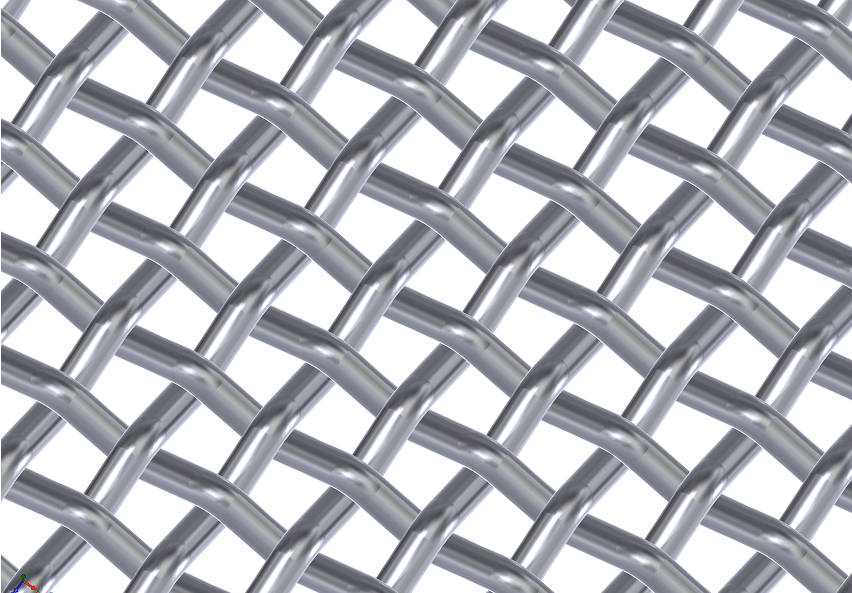

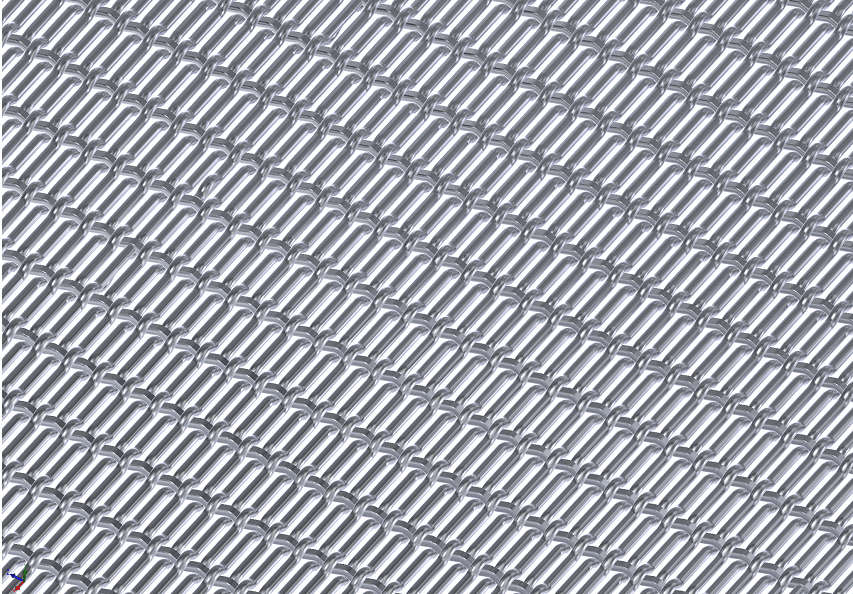

Grilgirco (A)

Wire Ø 0.5 to 3 mm

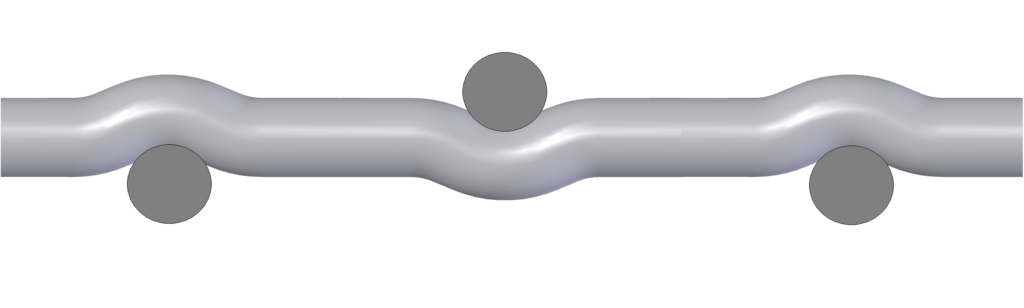

These cloths correspond to the most elementary forms of preforming, characterized by a sinusoidal corrugation to guarantee perfect cohesion at the crossing points as well as cut-off quality.

Because of the relatively open angle of closure at the corrugations, this type of preform is obviously all the more sensitive to shocks the higher the mesh/thread ratio. This is also why this type of fabric is generally limited to the finest cuts.

Standard range: (for other dimensions, please consult us)

- Mesh size: 0.7 mm ≤ W ≤ 40 mm

- Wire: 0.5 mm to 3 mm

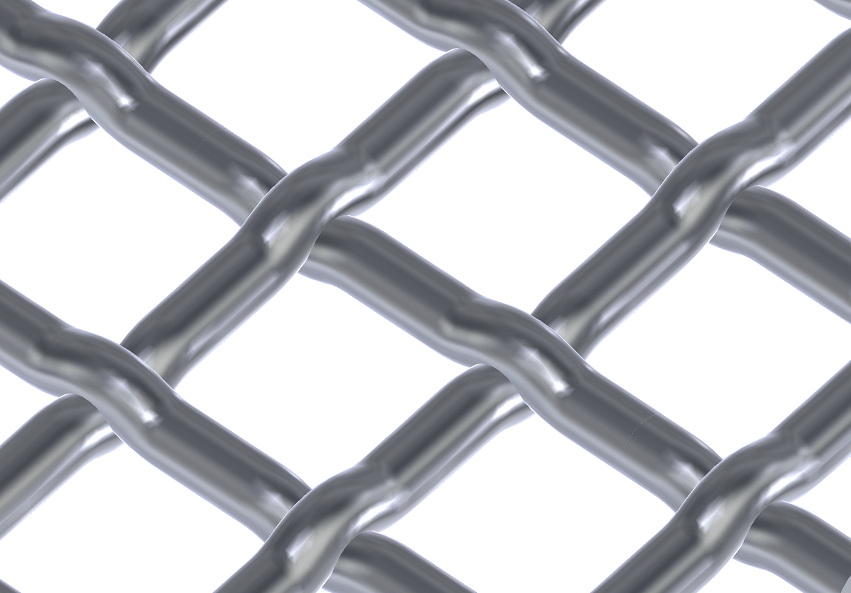

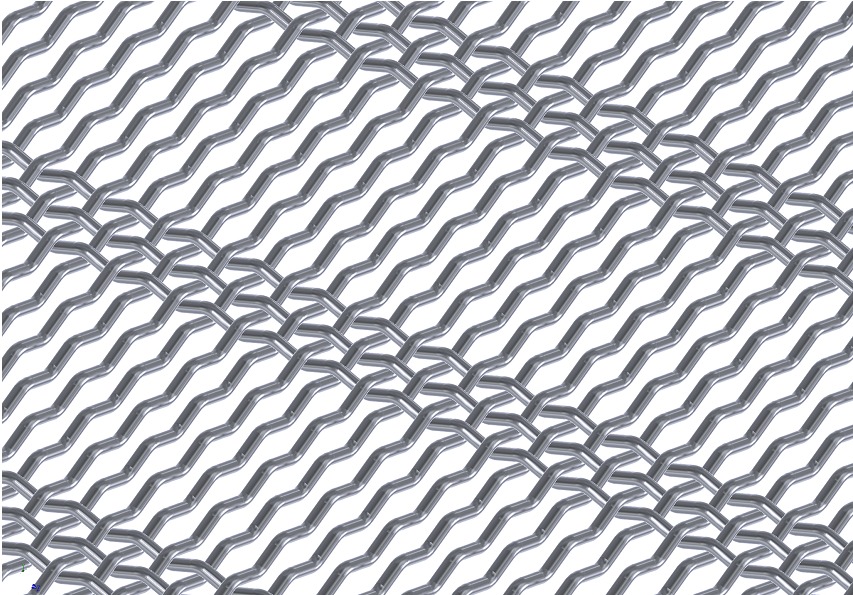

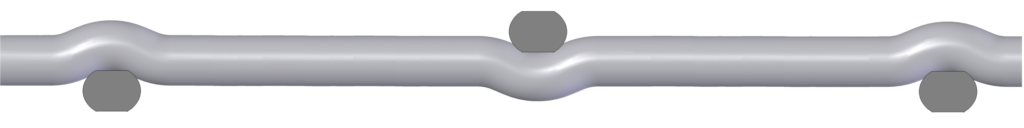

Plangirco/Plandur (D)

Ø 4 to 20 mm wire

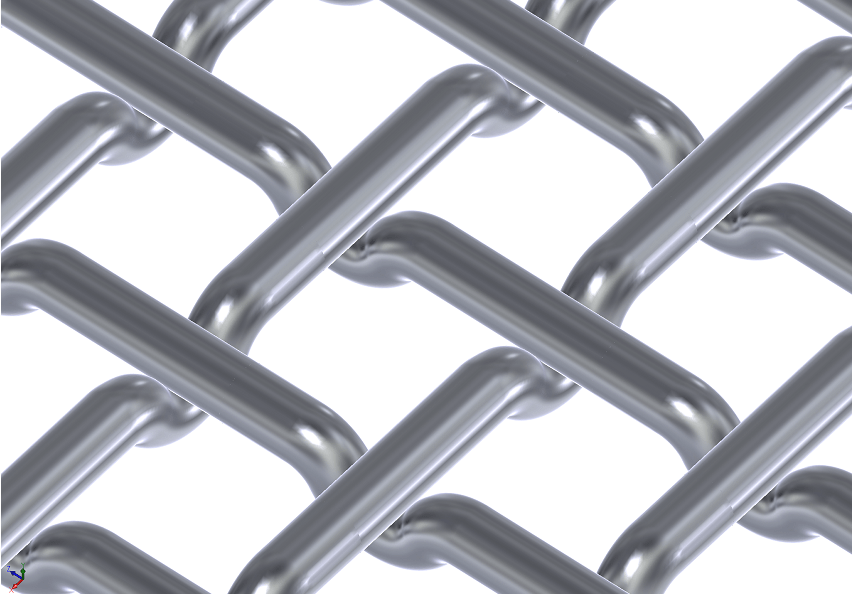

These fabrics are an evolution of the Grilgirco preforming form, characterized by a more pronounced imprint at the crossing points of each wire.

GIRON preforming ensures that the threads are better anchored in their original positions, enabling Plangirco fabrics to withstand high stresses.

The result is a long service life unmatched by competing products.

This type of cloth is particularly suitable for larger cuts, especially in the PLANDUR version (Wire ≥10 mm), which, thanks to the use of special steel, can withstand even greater impacts without the risk of breaking.

Standard range: (for other dimensions, please consult us)

- Mesh size: 7 mm ≤ W ≤ 200 mm

- Wire: 4 mm to 20 mm

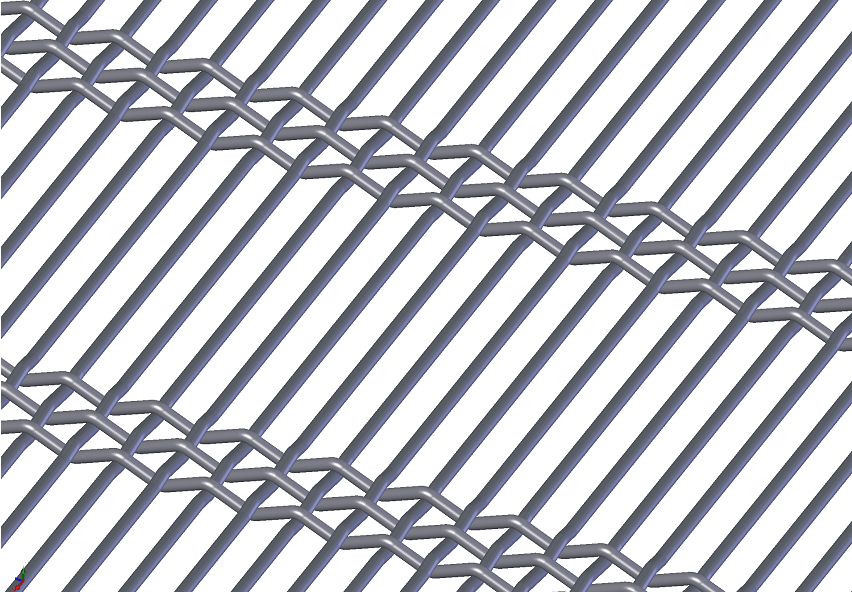

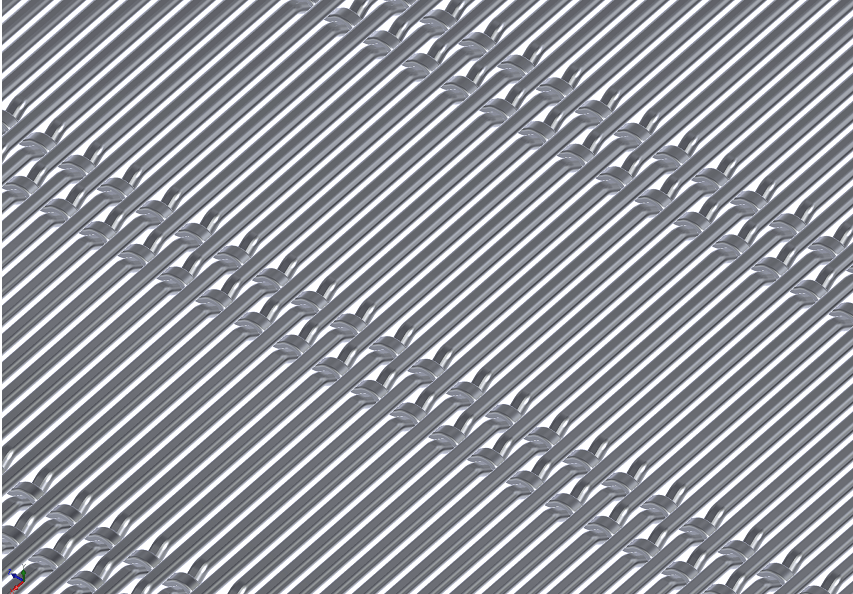

Plangirco flat surface (E)

Ø 4 to 8 mm wire

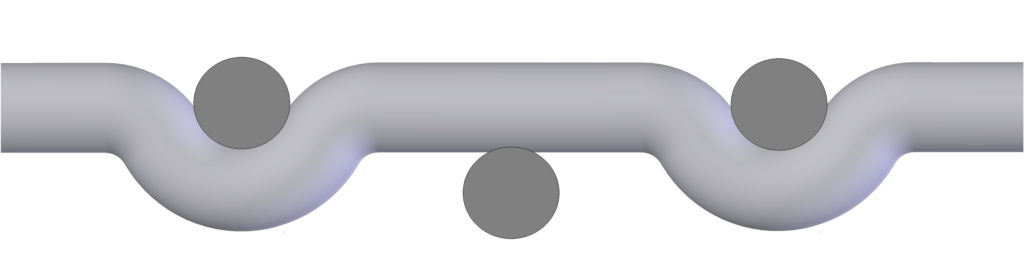

These canvases represent the ultimate refinement in the quest for a maximum durability for traditional steel grates. GIRON guarantees unequalled longevity and a minimum of 30% superior to all other types of preforming.

By combining closed-angle stamping and wire stamping at each crossing point, GIRON preforming ensures maximum transfer of material in contact with screened products, and eliminates any risk of relative movement until complete wear.

Plangirco's flat-surface fabric is ideal for all medium-mesh applications where precision cutting and abrasion resistance are crucial.

Plandur Surface Plane versions are also available if screening applications are compatible.

Standard range: (for other dimensions, please consult us)

- Mesh size: 8 mm ≤ W ≤ 90 mm

- Wire: 4 mm to 8 mm

CONTROLLED DEADLINES

A guarantee of professionalism and trust, we are committed to delivering your order as quickly as possible. Choose our quality services now.

Rectangular mesh

Longrilgirco and Longrilgirco harpée (LGG)

Thanks to their rectangular mesh, these meshes can make an effective contribution to improving flow, reducing studding or light clogging, or even serving as a de-puffer.

The "harpooned" version maximizes the mesh length/width ratio, which can reach a value of over 50.

In this case, the anti-clogging performance can be very interesting at a lower cost than specialized cloths in this field (see anti-clogging fabrics); on the other hand, this version may be a little less appropriate if you're looking for high cut-off precision.

However, the use of rectangular meshes should be limited to cases where the passage of flat elements does not affect the quality of the desired throughput.

Standard range: (for other dimensions, please consult us)

- Mesh: 0.4 x 1.2 mm ≤ W ≤ 15 x 153 mm

- Wire: 0.5 mm to 3 mm

Lonplangirco / Lonplandur and Lonplangirco harpée (LPG)

These cloths have the same functions as Longrilgirco cloths, but with a preform better suited to large or medium cuts.

Flat-surface production is also possible.

The Lonplandur version uses a steel that is slightly less effective in terms of pure abrasion, but more resistant to impact.

Standard range: (for other dimensions, please consult us)

- Mesh: 5 x 29 mm ≤ W ≤ 90 x 150 mm

- Wire: 4 mm to 16 mm

Planharpe (PLH)

They differ from LONGRILGIRCO HARPEES by the fact that the warp threads are straight between the groups of 3 weft threads, thus avoiding slanting.

As the wires are straight, there's no possibility of stretching them, so the fabric won't flutter and be destroyed prematurely due to lack of tension.

Standard range: (for other dimensions, please consult us)

- Mesh size: 1 x 50 mm ≤ W ≤ 12 x 50 mm

- Wire: 1 mm to 2.5 mm

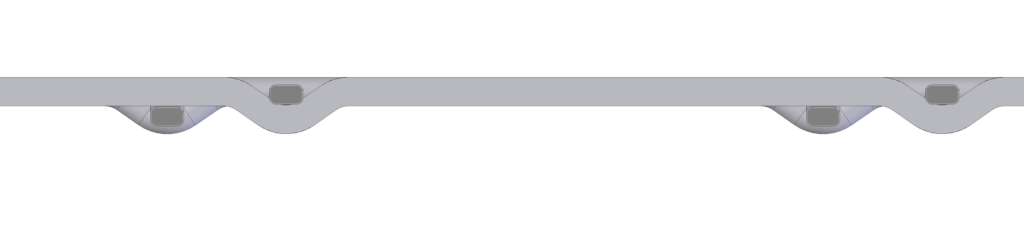

Lonmiplan (LMP)

These meshes have an optimized profile, mainly reserved for fine or very fine mesh.

Precision This rectangular-mesh fabric has the distinctive feature of having threads in the same plane between the warp and weft crossings.

As the chain wires are straight, this prevents the material to be screened from passing through at an angle.

Solidity The shape of the corrugation means that the angle of anchorage is much smaller. As a result, the weft is securely locked in place, preventing fine particles from the screen from entering between the wires and wearing them down.

The specific preforming of the warp and weft wires ensures very precise cutting and good mechanical resistance until complete wear.

Standard range: (for other dimensions, please consult us)

- Mesh: 0.26 x 7 mm ≤ W ≤ 6.4 x 13 mm

- Wire: 0.5 mm to 2.5 mm

Planfiss (PFS)

These screens are designed for screening materials that produce clogging "fines" during processing (e.g. fertilizers).

They are preformed to produce a perfectly flat work surface with parallel wires, guaranteeing both excellent cutting precision and good mechanical strength.

What's more, the flat surface has the advantage of producing fewer fines on soft products.

Standard range: (for other dimensions, please consult us)

- Mesh: 0.6 x 25 mm ≤ W ≤ 6 x 25 mm

- Wire: 0.5 mm to 2.5 mm