Screening technologies

To choose the appropriate woven wire cloth, it is necessary to understand how it wears down over time. With use, as a result of the abrasive effect of materials, meshes tend to flatten out and their raised parts are eroded. Abrasion resistance to fight wearing of screening materials is therefore a decisive objective in this choice. Several variables come into play:

1. Type of material used for the manufacture of screens, metal vs. synthetic

2. The appearance of the surface in contact with the product to be screened

3. The quality of tooling and the manufacturing process of the woven wire cloths

An ISO standard defines the prerequisites for the production of woven wire cloths (tolerances, requirements, verification methods, etc.). The European designation of a high resistance steel woven wire cloth can be misleading as it is allowed for wire with resistance in excess of 80 kg / mm². This designation alone is not enough to compare woven wire cloths from various manufacturers.

Woven wire cloths are now mostly made from the same steel grade, commonly known as “screen wire”. This is actually a carbon steel, very similar to the steel wire made to make springs. Its final resistance is obtained by cold drawing.

To produce woven wire cloths, GIRON has selected steels with enhanced characteristics combining a carbon content of at least 0.5% in order to guarantee high wear resistance and strong resilience allowing absorption without creating fragility:

1. The deformations required for preforming wire before weaving

2. The mechanical stresses caused by the vibration of the screens, even at high energy.

3. Impacts of materials and products running over the meshes

The surface appearance resulting from preforming

As we have indicated, abrasive wear occurs by the friction of materials with the screening surface. It is therefore easy to understand that the flatter the surface, the less the screened product meets raised elements against which it will rub.

The type of preforming is therefore of extreme importance for reducing the wear of woven wire cloths whose lifetime depends on the amount of material that can be worn without the meshes becoming deformed and the wires becoming loose.

1. “Simple crimp” preforming (model: Grilgirco)

This preforming corresponds to forms A, B and C defined by the ISO4783/3 standard. It is the most basic form of wire crimping. The operation consists in deforming the steel wire in a single sinusoid shape.

The weaving of these wires (warp and weft) produces a surface composed of projections and recesses for levelling equal to a wire diameter.

Due to a relatively open closing angle at the crimping level, this type of preforming is obviously particularly sensitive to impacts when there is a large mesh/wire ratio.

In addition, under the effect of abrasion, erosion or wear of the crimp heads (bumps) prevents products from moving forward and leads to breakage of the wires before the screening surface is really worn.

For reasons related to manufacturing costs, however, this preforming is commonly used for apertures of smaller meshes and finer cuts, i.e. generally less than 10 mm.

2. “Half-notch crimp” preforming (model: Plangirco)

This preforming corresponds to form D defined by the ISO4783/3 standard. This straight crimp is an evolution of the single crimp (form A).

The search for improved abrasion resistance has led to the development of a preforming technique which is characterised by a stronger impress at the intersection points of each wire.

The weaving of these wires (warp and weft) reduces projections (bumps) by transferring as much metal as possible towards the work surface, with a levelling limited to 1/2 the wire diameter.

The life of the cloth will be lengthened compared to a simple crimp. This type of “half-notch” preforming is commonly used on weave apertures in excess of 10 mm.

3. “Flat-top surface crimp” preforming (model: flat-top surface Plangirco)

This preforming corresponds to form E defined by the ISO4783/3 standard. This crimp is the ultimate development of wire preforming in the search for maximum screen durability. Not only does the screening surface have hardly any projections (bumps) but the maximum metal available is transferred to the work side.

By combining a closed-angle stamp and wire die at each intersection point, this preforming removes any risk of deforming the screening surface until complete wear of the screen.

This “flat-top surface” preforming is naturally effective in its chosen field in medium cuts and weaves (10 to 40 mm) where precision cutting required by aggregate standards and abrasive wear resistance are critical.

The controlled lifetime on several installations ensures peerless durability which is at least 30% to 50% higher than any other type of preforming.

GIRON uses this “flat-top surface” preforming as standard on the 8 mm mesh portion and for all meshes using wire with a diameter between 4 mm and 8 mm.

The quality of tooling and the manufacturing process of the woven wire cloths

The quality of the steel wire and type of preforming, although these two parameters are very important, are far from enough to obtain a very good screening cloth. If the tools are not well designed, if the machines do not have the required power and precision, the meshes will not be regular, and the wires will loosen and will wear prematurely by lapping.

The GIRON company has therefore developed and finalised its own machines, processes and unique techniques for producing very high quality steel screens.

The choice of material

There are no specific standards today to define the prerequisites for the production of synthetic woven cloths (tolerances, requirements, verification methods, etc.). In this area, two basic materials are used: rubber and polyurethane.

But how should a good basic material for making screens be defined?

1. Rubber

Rubber is the result of the homogeneous mixing and transformation of several ingredients of different kinds and coming from different sources. Originally, rubber is made from natural latex taken from certain plants. With industrial development and new technology, rubber can also be manufactured synthetically (SBR, NBR, etc.) from derivatives of fossil fuels.

Complex mixing and formulation now make it possible to obtain technical and high-performance rubbers to suit the application.

The main properties of rubber are its elasticity, seal and shock absorption. These three parameters are valuable in the field of screening, especially when processing large sizes to absorb shocks or reduce noise.

However, fighting wear remains paramount and other parameters are also to be considered such as resistance to tearing, heat and chemical agents, its implementation during the vulcanisation process but also screening conditions.

Rubber shows good results in wear resistance by deformation and / or cutting. However, the thickness must be sufficient to absorb the shock of the material on the screening surface. In addition, the angle of impact of the material also plays an important role on the level of wear, in particular its resistance to tearing.

As such, GIRON continuously works with suppliers to determine the optimal formulation of its high-performance rubber based applications such as the screening of hot products, chemicals and abrasives.

2. Polyurethane

Launched in the 1930s in Germany, the use of polyurethanes (polymer family) became widespread after World War II, replacing nylon or rubber.

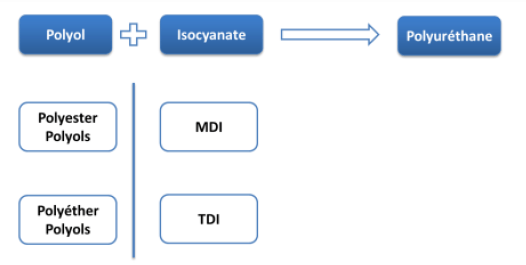

Polyurethane (urethane based) is the result of the chemical reaction of an isocyanate and a polyol.

There are three major technical families: flexible foam, rigid foam and non-foaming polyurethanes.

Foam polyurethanes represent 2/3 of the market.

In the late 1970s, polyurethane (non-foaming group: elastomers, adhesives, coatings) appeared in screening technology and materials processing.

Like rubber, polyurethane is derived from mixtures and complex chemical formulas where the choice of ingredients enables different levels of performance to be achieved depending on the application. It is all about compromise.

Depending on screening conditions and the type of material, it is therefore possible to improve the properties of polyurethane screens.

The abrasion loss, according to the DIN 53516 standard, in theory allows the comparison of the performance of various polyurethane grades. However, the actual screening conditions of screening surfaces are very far from this standard test and choosing the best quality is mainly based on the experience of the manufacturer or on the internal development of testing procedures that are as realistic as possible.

Regardless of the choice of the grade, the choice of hardness (expressed as shores) is very important in abrasion resistance. Indeed, the nature, form and mass of screened materials have varying impacts which will in theory be better tolerated by low hardness. Bilayer productions are therefore commonly used.

In our case, the polyurethanes used may be hot-cast and, given the requirements both in terms of mixing ratios of the components and of implementation temperature, the use of a casting machine is almost always indispensable.

The abrasion resistance of the screening surface will directly depend on compliance with implementation conditions recommended by the material supplier: temperatures of casts, firing temperature and drying temperature and time). Again, the final product qualities will depend on experience and the care taken during the process.

As such, GIRON works continuously to design and build ever more efficient materials in terms of abrasion resistance. We regularly work with our suppliers to identify the optimum formulation of our high performance polyurethane based applications such as the screening of abrasive materials, dry or underwater screening, or many others.