The modular system has been designed to facilitate screen media assembly/disassembly operations, making maintenance easier for operators.

Being smaller than a stretched fabric, the module is lighter and easier to install. Modular system assembly consists of assembling several modules, generally 1 meter long and 300 mm wide, on a screen deck.

Since polyurethane has a high elongation capacity, the modular panels need to be reinforced with steel inserts to guarantee good mechanical strength and withstand the load imposed by the materials to be treated.

For installation, these modules are manufactured with different finishes, depending on the mounting model chosen by the customer. There are several on the market, the most widespread of which is the "WS 85" system, invented by our colleague in the 1980s. GIRON offers the majority of existing mounting systems, and our teams can help you choose the most advantageous solution for your installations.

GIRON offers a wide range of mesh sizes (W) to meet the needs of its customers.

Standard range: (for other dimensions, please consult us)

- Square mesh: 3 mm ≤ W ≤ 150 mm

- Rectangular mesh: 4 x 10 mm ≤ W ≤ 27.5 x 61 mm

- Injection cracks: 2 x 11 mm ≤ W ≤ 1.5 x 11 mm

- Mesh size: in rows or in staggered rows

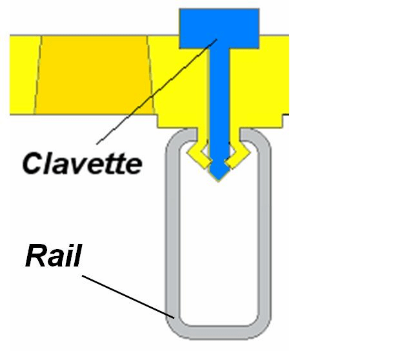

Modular key system - Type MGI

The modular key system is a GIRON patent, registered in the 90s. The principle consists in locking the various modules to the screen frame by inserting a key between each panel in the slot of the fixing rails.

It's one of the most effective solutions for simple, easy and fast assembly, especially for installation in confined spaces in a vibrating screen.

The rail and wedge fastening system holds the panels securely in position, while allowing easy, effortless assembly and disassembly with a simple screwdriver. A notch is provided for leverage. Depending on the height of the wedge head selected, it can act as an integrated deflector, deflecting product or water away from the screening surfaces along the entire length of the module.

As the modules are manufactured with side jambs, they position themselves easily and automatically in the rail slot, thus benefiting from great stability and avoiding any risk of falling between floors and fixing rails. These advantages considerably improve working conditions for operators, while reducing the risk of injury and intervention time.

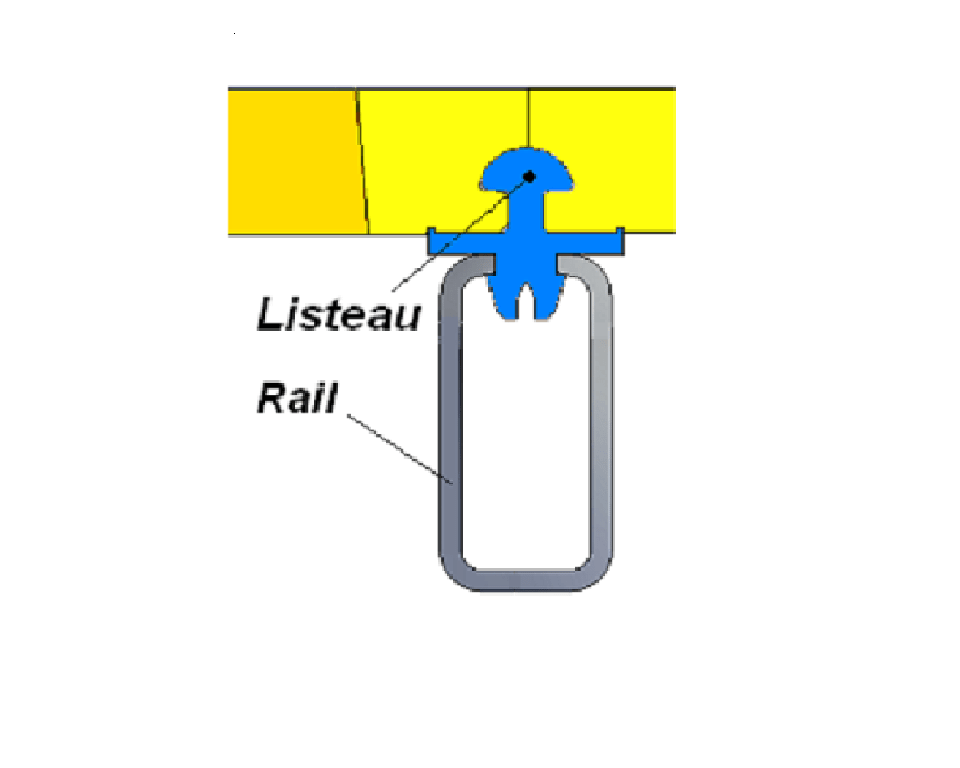

Modular listel system - MIG type

The modular listel system was developed in the 80s. The principle consists in force-fitting the various modules onto the screen frame by inserting a listel into the slot of the mounting rails with a mallet.

This is one of the most widespread solutions on the market.

The listel fastening method ensures that panels are held securely in position. By first inserting one side of the module with a groove into the listel, then using a mallet to force the second side of the module into the next listel.

Disassembly involves inserting a screwdriver or other tool into the module's meshes to pry the module off the listel. Care must be taken not to damage the mesh if the panels are to be reused.

Assembly/disassembly operations on the MIG system are quite demanding for maintenance teams, many of whom prefer the MGI-type key assembly system, which is easier and quicker to implement.

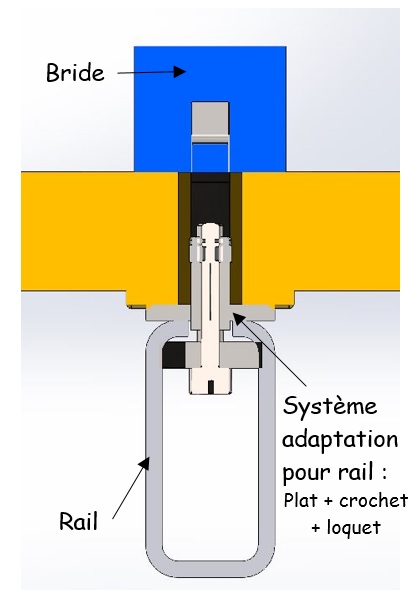

Modular clamping system - Type MMG

The modular clamping system consists in locking the various modules to the screen frame by clipping a polyurethane part, called a "mouse", "wedge" or "clip", into a hook previously fixed in the slot of the mounting rails.

The corners act as deflectors, deflecting product or water onto the screening surfaces and limiting run-off onto solid areas.

The clamping method holds the panels securely in position, preventing them from sliding into the rails once they're in position. The module is positioned on the rails by protruding the hooks into the notches provided. Then, by tapping horizontally with a mallet, a polyurethane wedge is clipped to the hooks. To dismantle, loosen the polyurethane wedges with the mallet.

MMG system assembly/disassembly operations are relatively straightforward and quick for maintenance teams, but many still prefer the MGI-type key assembly system because of the weight of the polyurethane panels and the number of wedges required.

Different types of side mounting

(compatible with all modular systems: MGI, MIG, MMG)

Mounting with baseboard and clamping bolt

Mounting with baseboard and clamping wedge

Mounting with skirting board, blocking strip and clamping wedge

Installation with integrated baseboard